New safety features for earthing and short-circuiting devices

Earthing and short-circuiting devices: Safety comes first

Earthing and short-circuiting devices are indispensable safety components in switchgear and transformers. In accordance with the regulations of the DGUV (German Social Accident Insurance) and DIN VDE 0105-100, they are subject to regular inspections to ensure safety when working on electrical systems. In this blog post, we present two simple, innovative new features from Horstmann that significantly improve the safety and user-friendliness of these devices.

When should earthing and short-circuiting devices be replaced?

There are certain criteria that indicate that an earthing and short-circuiting device must be replaced:

- Devices that have been exposed to the full short-circuit load.

- Devices whose rope cover is not transparent or is damaged.

- Devices whose originally transparent and colorless rope cover is so discolored that the condition of the copper rope is no longer recognizable.

- Devices with welded or soldered connections.

- Devices in which conductor cables have pulled out of connectors or connecting parts.

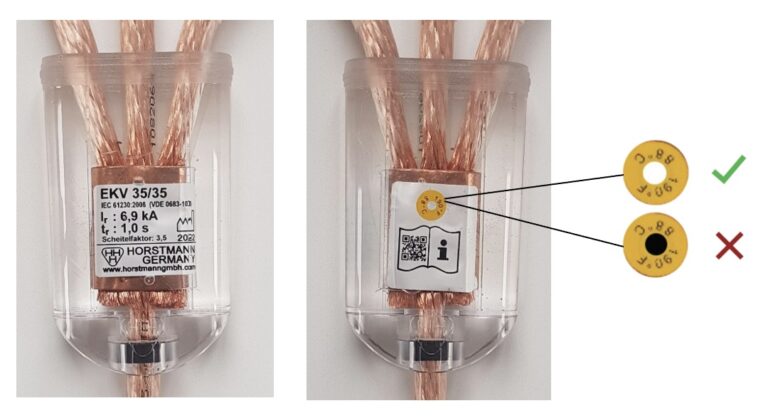

Temperature sensor on connecting element of earthing and short-circuiting devices ensures increased user safety

One of the innovations in Horstmann’s earthing and short-circuiting devices is the integrated temperature sensor. This is located at the heart of each device and was developed to increase user safety. If the temperature exceeds the permissible limit, the temperature measuring point is activated, which is indicated by an irreversible change in color from white to black. This visual signal makes it easy to identify devices that have been exposed to a short-circuit current. Such devices should be immediately removed from use and replaced. This additional safety mechanism therefore helps users to visually inspect earthing and short-circuiting devices and ensures increased user safety.

Quick access to digital instructions for use via QR code on the connecting element of earthing and short-circuiting devices

Another practical feature that Horstmann has integrated into its earthing and short-circuiting devices is a QR code in the connecting element. This QR code allows users to easily access the digital version of the operating instructions via smartphone. This is particularly useful for quick information on site and makes it much easier to operate and use the devices safely. The sturdy and transparent cover of the fastener protects the QR code from damage and is designed for a long service life.

Summary

Horstmann’s new earthing and short-circuiting device features an integrated temperature sensor in the connecting element to detect critical heating. If this temperature measuring point is activated (by the discoloration from white to black), the device should be replaced in accordance with the recommendations of IEC 61230, as it has been exposed to a short-circuit current.

The addition of a QR code to the heart of every earthing and short-circuiting device allows users to easily access the digital version of the operating instructions via smartphone.

With the new safety features, the temperature sensor and the QR code on our earthing and short-circuiting devices, we are setting a new standard for safety and user-friendliness. Horstmann remains true to its mission to make the medium-voltage working environment safer and more efficient.